Helping Businesses in Construction Meet Emission Reduction Deadlines

Energy and fuel used on construction sites accounts for approximately 33% of total emissions from England’s construction industry. (Strategic Forum for Construction 2010 Carbon Assessment Report)

The construction industry in the UK is under pressure to meet new emission reduction targets and deadlines across London and the UK. London has announced that both road and non-road machinery will need to meet new standards by 2020 and European regulation is bringing in Stage 5 requirements for engines of all sizes by 2019/2020. The main focus is on the reduction of small particulate matter and NOx emissions - estimates in 2013 on non-road moving machinery (NRMM) used on construction sites suggested it was responsible for 7% of NOx emissions, 14% for PM2.5 and 8% of PM10 emissions in Greater London*.

What are the options for firms needing to meet these targets? Construction firms will need to utilise the new Stage 5 generators for their sites to meet the legislative requirements, however due to the inclusion of additional exhaust elements to reduce NOx and particulates these units have a bigger footprint than their predecessors for the same power capacity, in addition they will need to run at 30 -40% load consistently to avoid damaging the filters. As construction sites often have varying demands for power during the day and night the average is generally closer to 10% load over a 24 hour period which is not ideal. So how do you address this issue and meet the new legislative demands?

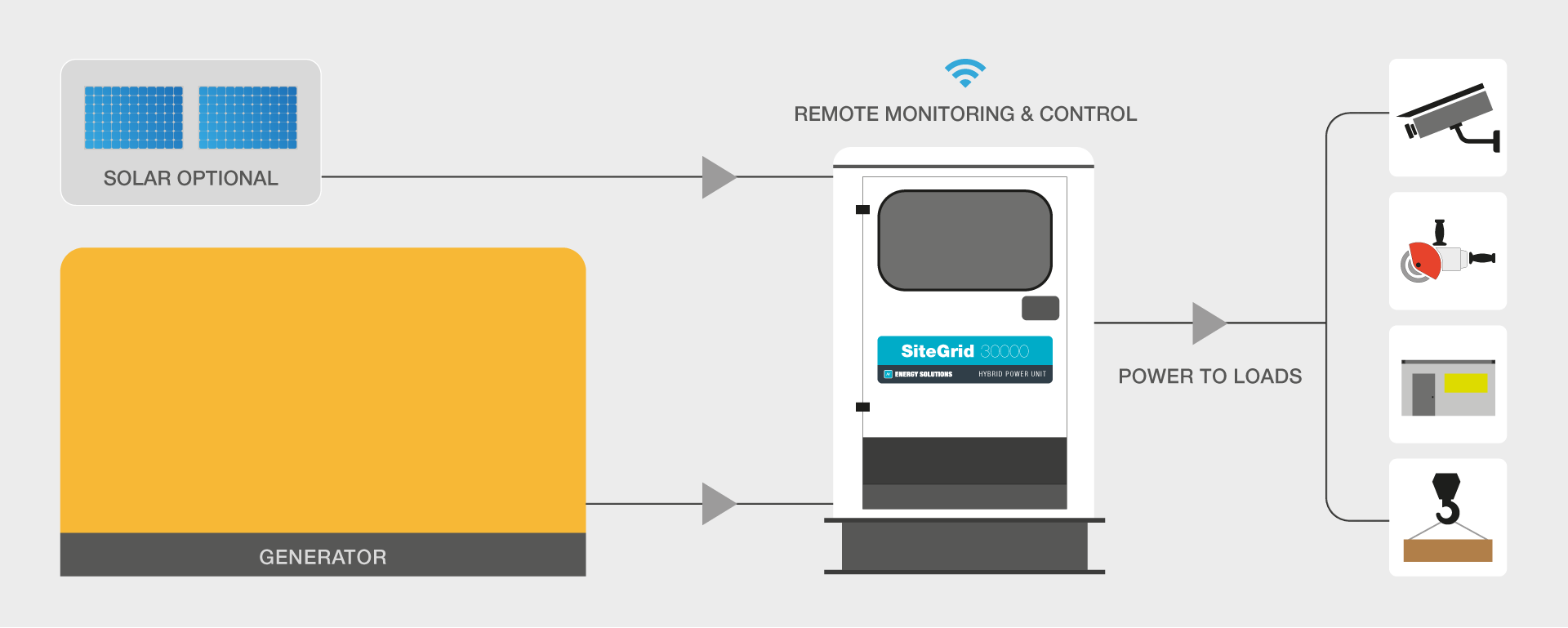

SiteGrid now provides the solution to these problems – it can be connected with a smaller capacity Stage 5 generator allowing the same loads to be met more efficiently, with lower fuel costs and lower emissions. The generator will run when demand is high but when demand is low the genset will switch off automatically and the SiteGrid will run those loads directly (things like site cabins over night or security lighting). During the day when loads pick up again the generator will start automatically and if the loads increase further both the generator and SiteGrid can work simultaneously for a period to power the demand.

This ensures that generator is correctly loaded when running reducing filter problems which can damage the machine and reduce up time.

SiteGrid Overview

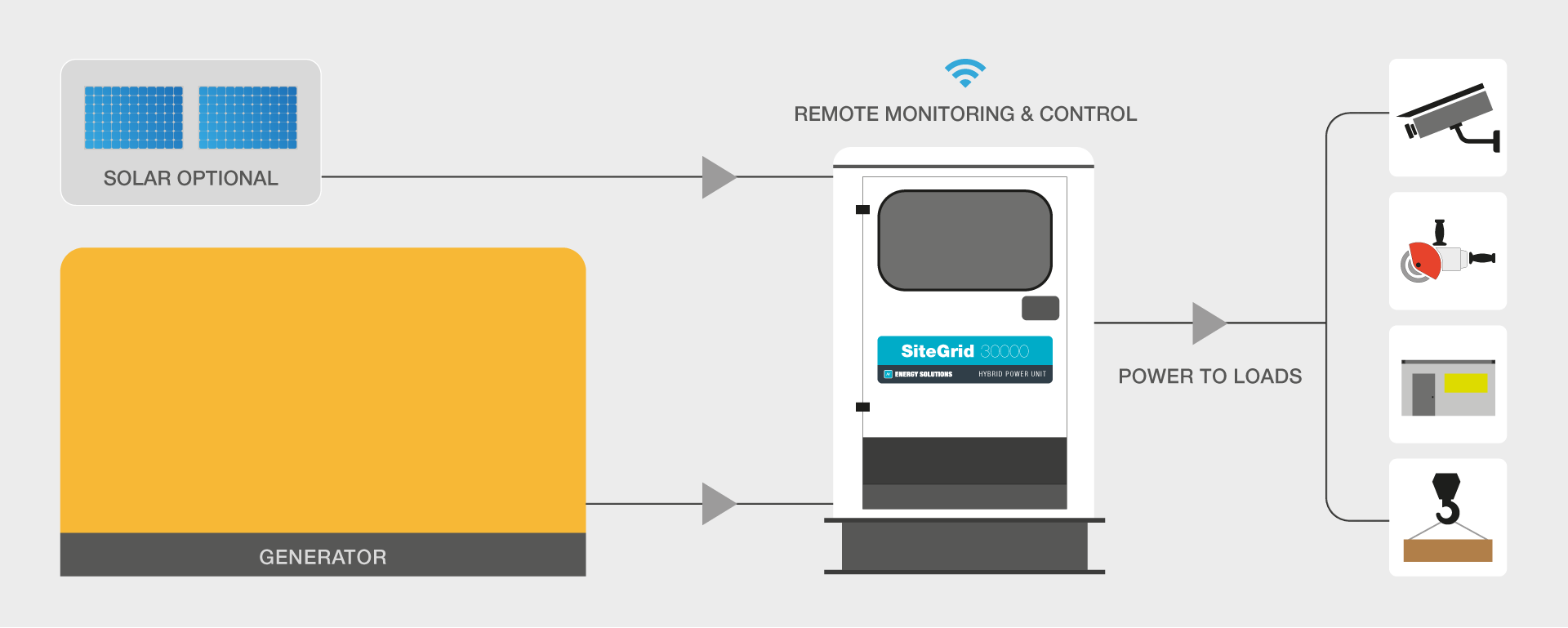

The SiteGrid will directly supply power to loads up to 30kVA from it’s internal battery bank, this can be charged either by renewables or by a generator. Power will be stored in the battery bank until needed and the connected generator will only need to start when loads are sufficiently high or the batteries are discharged. By only running when needed the generator will be more efficient, generating less soot and noise.

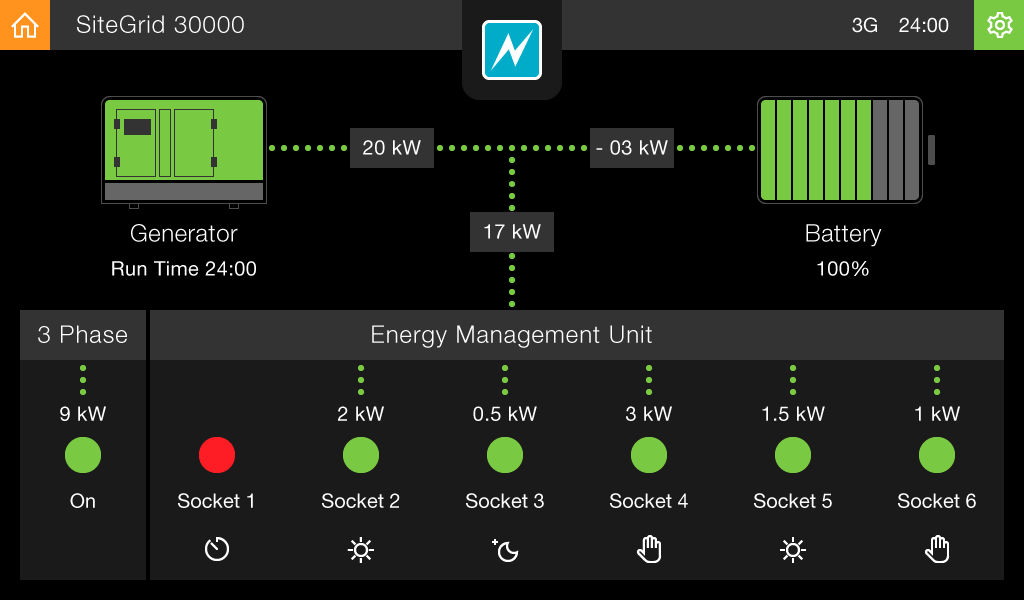

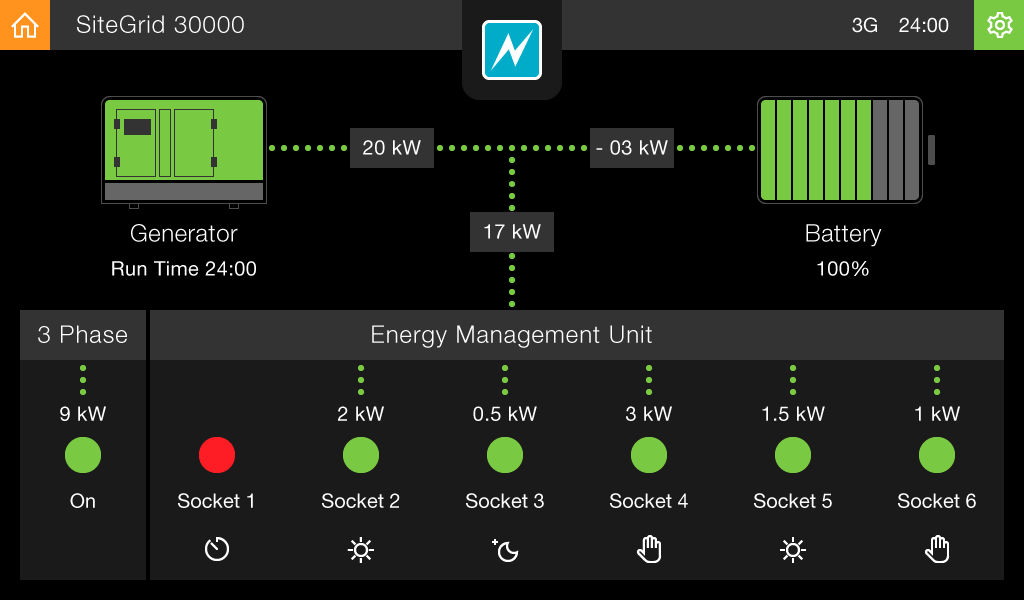

SiteGrid also features a unique Energy Management Unit (EMU) to bring more sophisticated control for sites with a variety of power requirements. The EMU allows 6 separate loads to be fed from the unit and programmed with their own unique schedules. For example – one feed could be for security lighting that is triggered by the in-built light sensor, another could be for the drying cabin that does not need to be heated during Saturday and Sunday.

The Energy Management Unit Front Screen

The units are being launched in October with demo units available for one week’s free trial to clients interested in trying out SiteGrid on their own site. Mark Penny, Head of Sales at Energy Solutions explains the purpose of the demonstration units, “We know for construction companies the requirement to meet these new emission reduction deadlines is an additional cost in the short term, but long term the SiteGrid unit will not only help them meet the deadline but also reduce their costs. A trial of the unit will allow them to see the full potential of that saving”.

If you are interested in the trial program please contact Mark Penny at sales@energy-solutions.co.uk

*NRMM Website 2017 http://nrmm.london/content/cleaner-construction-machinery-london

Note to Editors

Further information, images and interviews can be requested from Melanie Lay

melanie.lay@energy-solutions.co.uk

07802 874451

01634 290772

FIND OUT MORE

Download high resolution images

SITEGRID IMAGES